R&D and prototiping

We collect ideas, design with creativity in order to apply technology and innovation. We generate new projects and constantly improve processes and products that are not new anymore…

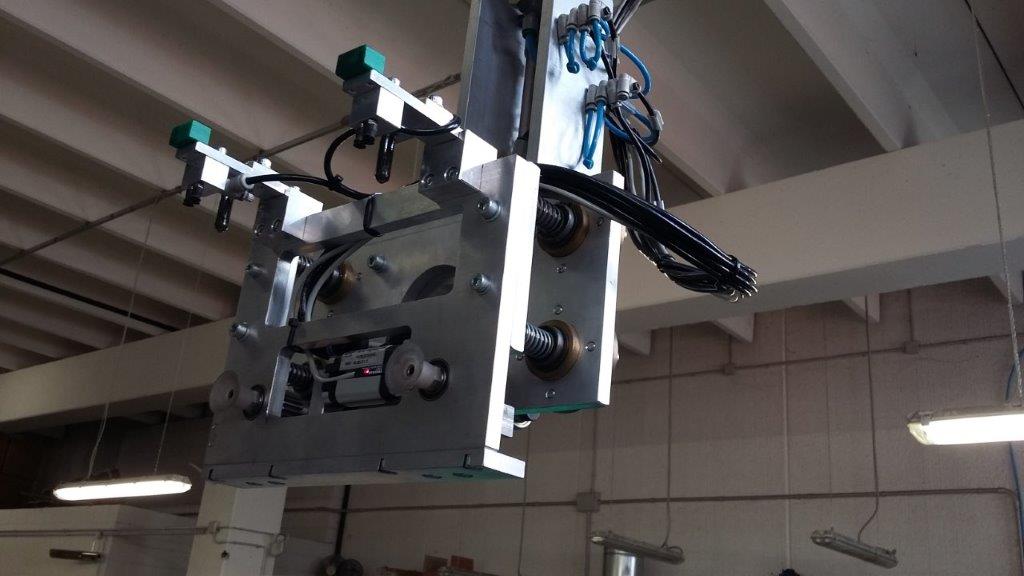

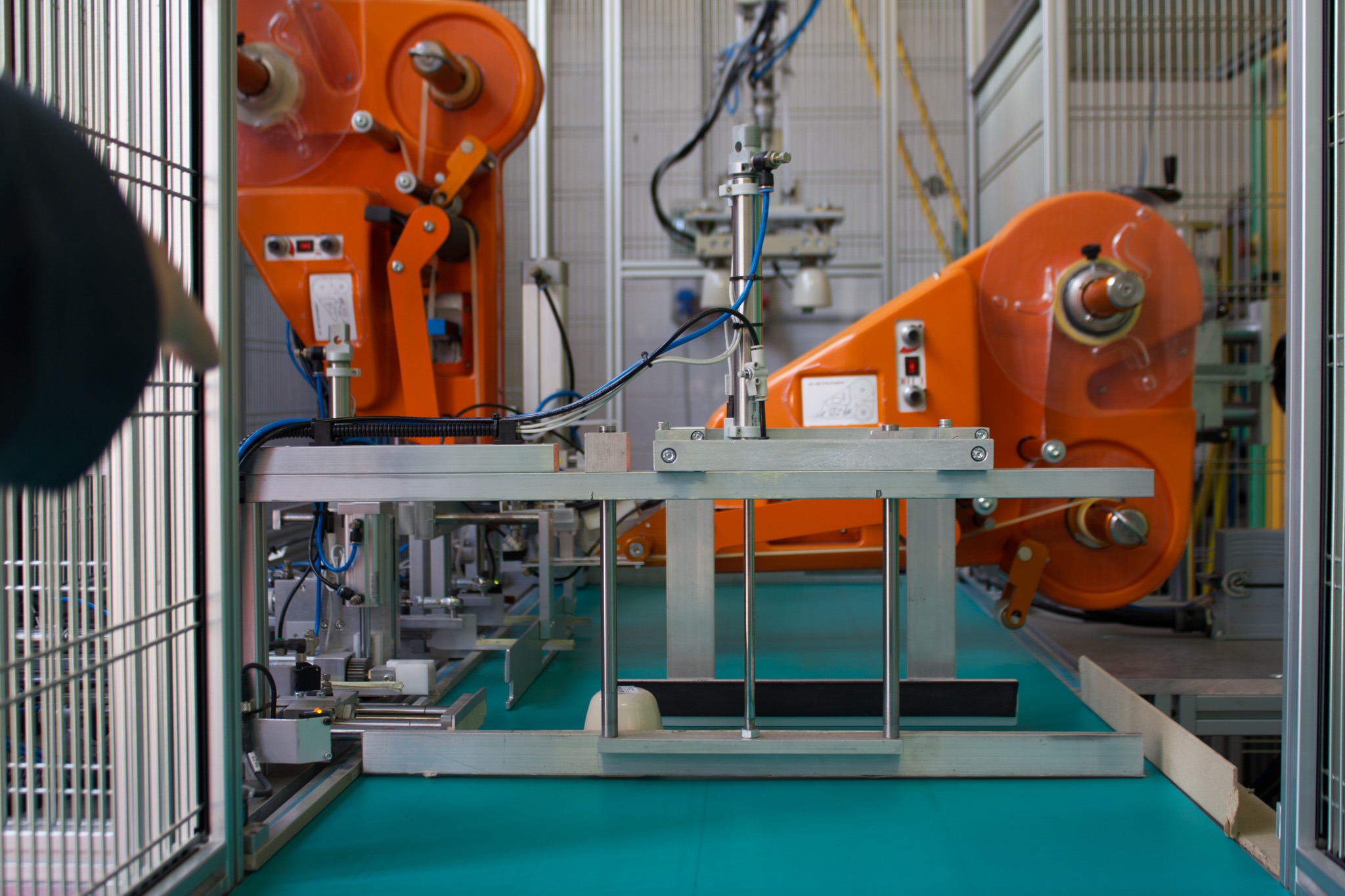

Automation

Our presses are equipped with 3 + 2 electric axes, with automatic labeling stations. We offer the possibility of accurate and precise manipulation on pieces of any geometry…

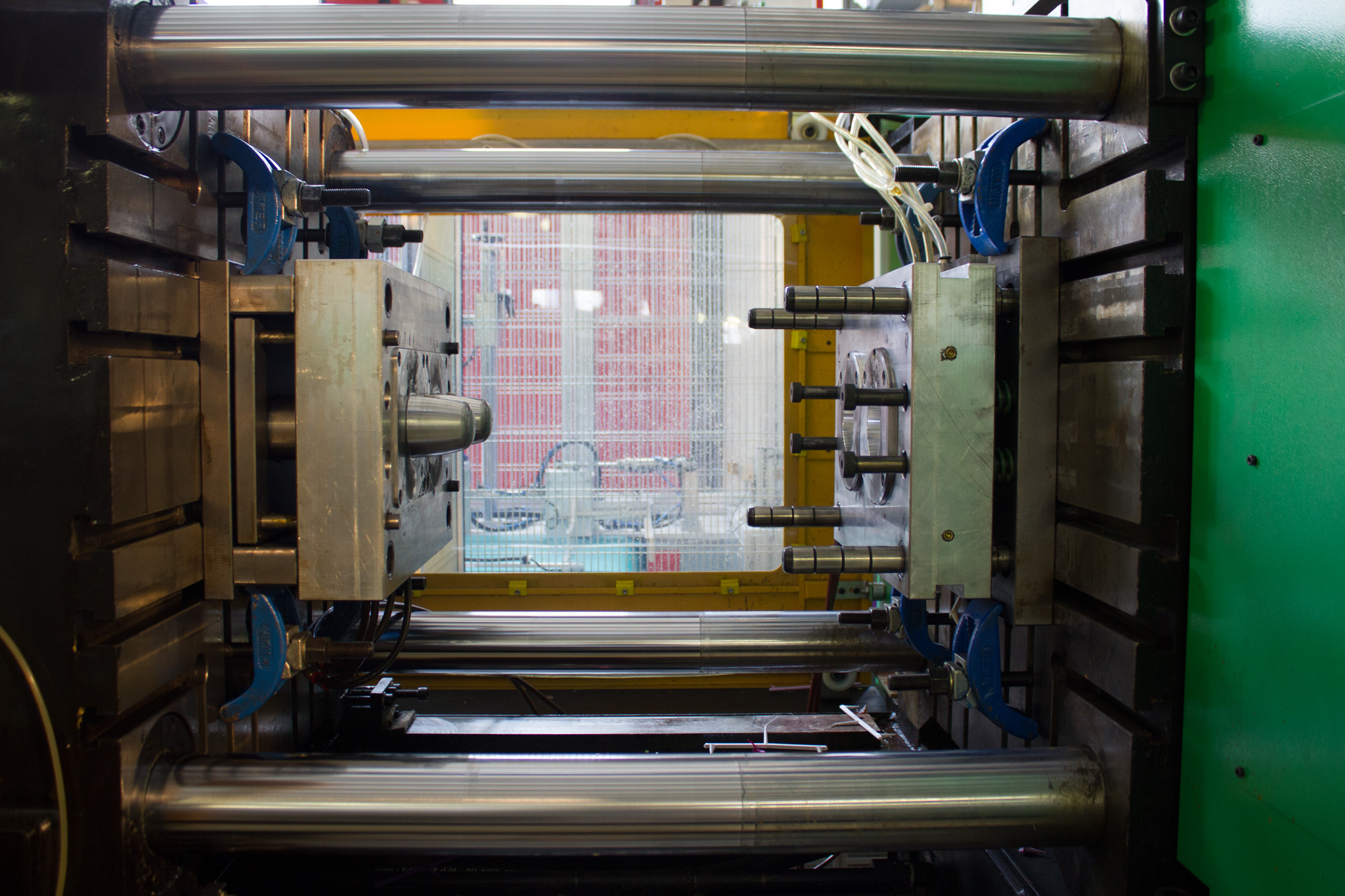

Injection Moulding

We develope products with injection moulding and horizontal and vertical presses. We transform any kind of termoplastic material, from the most common fiber charged PP, talc, in…

Quality

It represents one of the fundamental aspects required for an industry’s growth. Methods, instruments and continue instruction are the bases to assure a product which satisfies the quality level asked from our client. To assure high quaity standards we start from knowing that each levels and functions must be sensible and involved to reach the goal.

Our strengths

- Quick delivery

- Timeliness in order management

- In & out material flux rapidity

- Problem solving competence

- Pre-series sampling

- Little runs printing

These aspects and quality of the services are part of our way to think and operate; we are proud of this, but it’s also an effort and an everyday challenge.

"The future belongs to the ones who believe in the beauty of their dreams"

E. Roosvelt

Processes

We monitorize sistematically the processes while working on it, analyze and take care of timing and methods in each fase. This approach allows us to prevent inefficiencies, guarantee trackability to final user and effectively manage eventual non-compliances. We share lean filosophy and with enthusiasm and determination work in team for continue improvement.

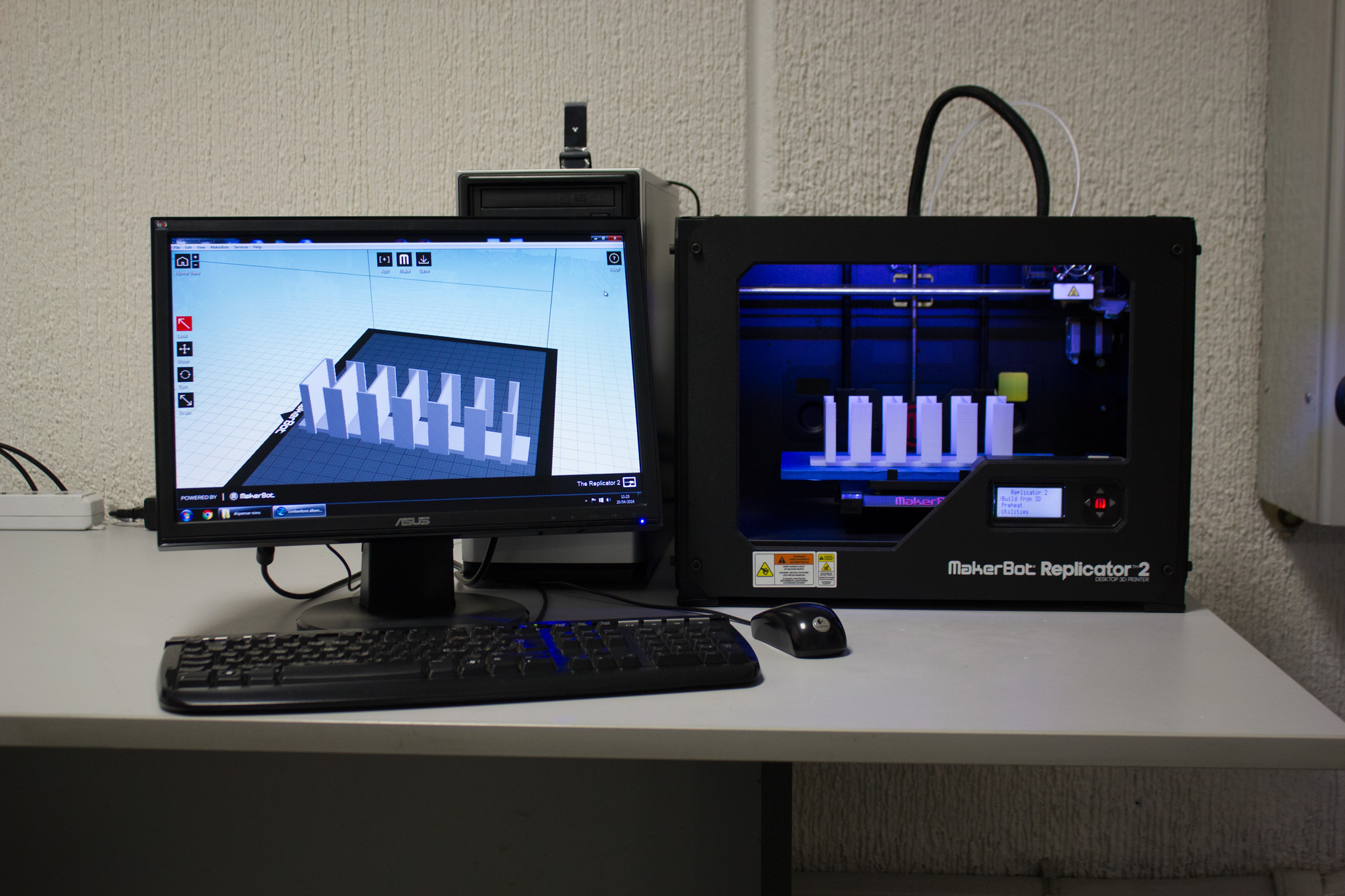

Research & Development

We research and offer innovative improved solutions. In sinergy with the client we analyze with technical competence the product’s critical issues. While designing we keep track of manufactures’ environmental impact in every single fase of its life cycle. The attention to the choice of recycled and recyclable materials, of efficient logistic structures and of disassembly easiness are the things that make Luxstamp an eco-efficiency and sustainability model. We develope prototipes with a 3d printer of aesthetic, mechanic, representative details in LPA material.

Safety and Environment

The profuse Luxstamp’s attention and effort aim to sensibilize all resources in safety’s and environment’s scope. This process already borns in the R&D fase to create an eco-efficient and eco-sustainable product. Our prevention policy and constant effort are aimed to worker’s protection and environment’s respect.

Collaborations

Every day we try to diffuse our filosophy with enthusiasm and desire to generate ideas to enrich the product with technical details and better design. We collaborate with companies who are leading in ermetic seals’ system, electric and sanitary components, high fashion accessories’ marketplaces. We proudly claim to be providers for this sectors that recognize us quality, reliability and service. We also collaborate with technologically equipped realities that deals with design, construction and maintenance of alluminium and steel molds.

Production

Our actual machinery offers the possibility to produce manufactured goods from the smaller 15T vertical press to the bigger 200T horizontal press. They are equipped with 3 axes robots and automatic insert’s loading and unloading stations. The principal developed activities are:

- Injection moulding of materials like: ABS, SAN, PMMA, PP, PE, PS, PA4.6, PA6, PA6.6,PA12, TPV, TPU, PC, PET G.

- Automatic and analogic insert printing.

- Molds’ polishing and lapping.

- Automatic labeling stations.

- Termo retraction.

- Assembly.

- Molds’ test, maintenance and tuning.

- High level Know how on printing processes and special finishings (chrome, metallization, water transfer printing, lacquering).

Patented solutions

"Underheels insert" industrial invention patent.

"Heel’s renforcing core" industrial invention patent.

Hydraulic system bench, tilted and rotating mold bench.

Magnetic insert products’ molding.

Research, Creativity and Design serving product’s innovation

Made in ITALY Development, Production and Solutions.

About Us

Our company was born giving products and accessories for high fashion footwear sector. We have kept and developed knowledge in this scope during time that allowed us to realize design products. We created facilities, automatized processes and working fases for product’s industrialization. We create and shape matter developing plastic manufactured goods, but not just that…

Realizations

View all products-

3 axes robots in action.